Do you use straps for securing cargo? If the answer is yes, then this article is for you.

Have you ever had a situation when your driver called you and informed that he was having a border control and got a ticket “for straps”? And although he insistently claimed that the “colour” and the number were right, that everything was ok … the ticket was still there and it had to be paid, and the driver could not explain for what exactly he got it.

It is worth knowing that the European standard PN-EN 12195-2 regarding cargo securing applies all over the EU. This standard requires that persons handling loading use flexible restraint elements, such as straps, chains, and ropes, as well as other specialist equipment, such as mats increasing friction, wedges, angles etc. This standard quite precisely stipulates the requirements that should be met by lashing straps; it also contains formulas for calculating the number of straps necessary to properly secure the cargo.

Let’s first debunk two myths

The “colour” of lashing straps does not guarantee their strength (although the stronger ones in fact are usually orange). The number of straps also is not the most important – what really counts is their strength and the way they are fastened.

The range of lashing straps is very wide. Below, you will find a few words about what is important and how to minimize the risk of getting a ticket for improperly secured cargo.

The most common straps can hold from 0.7 T to 7.5 T, they are from 25 mm to 75 mm wide and from 7.5 to 12 metres long. Of course, one can easily find straps 16 meters long and even order straps in a selected colour. When choosing a strap, it is especially recommended to look at the label, rather than a colour. The label is usually sewed in at the end of a strap. And while a colour of a strap may be a hint to identify its nominal strength, the colour of a label really always informs us about the material from which the strap is made. So:

– a label in a blue colour informs us that the strap is made from polyester (PET). These are the most common straps and the most universal ones. They retain their properties in the temperatures from –40 to +100°C and are resistant to mineral acids,

– a label in a green colour means that the strap is made of polyamide (PA). This type of strap works well in the same range of temperatures as a polyester strap, however, it is resistant to alkalis, but it is not resistant to mineral acids.

– a label in a brown colour means that the strap is made of polypropylene (PP). It maintains its properties in a smaller scope of temperatures: from –40 to 80°C and is not resistant to acids or lyes.

After choosing a right material, the parameters showed on its label are equally important. Although the numbers on the label are all Greek to anybody at first sight, let’s try to decipher them step by step.

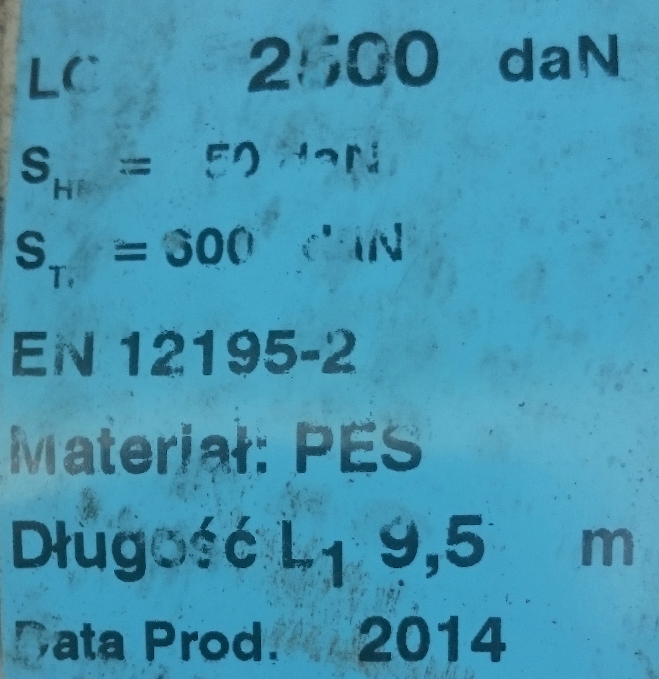

Photo: Label of a transport strap with the parameters: LC = 20 KN, that is 2000 daN (2 T, with strapping 4 T), extension below 7%, SHF = 50 daN and maximum STF = 10 KN = 1000 daN (so this particular strap meets also internal German and Austrian standards). LGF + LGL give us a total length of 8 m, and the note at the bottom – “EN 12195-2” confirms that the strap is complaint with 12195-2 standard

LC is the first and one of the most important parameters of a strap marked on a label; it stands for lashing capacity, that is a maximum allowed force on the strap which will not cause tearing, expressed in daN

As 1 daN = 1 kg, then 2500 daN is 2500 kg = 2.5 T. It is essential that, when lashing a load with a tie down strap (that is by looping it over the cargo, e.g. a pallet, and tying it on the both opposite sides of the floor) according to EN 12195-2 standard, capacity of a strap in a simple arrangement should be doubled, so the 2500 daN strap gives 5000 daN capacity. It means that a strap fastened this way with LC = 2500 daN will endure force equal to the weight of 5 tonnes.

SHF (standard hand force) is the second parameter

Note: most of the ratchets have the parameter SHF = 50 daN, which means that the ratchet is designed for a maximum pressure of 50 kg. That is why the straps cannot be extended by adding another piece which is at hand (e.g. a wheel wrench, wrench extension etc.). The strap should not be tightened also by standing on the ratchet: it may easily cause exceeding allowed force and consequently deformation and damage of the ratchet. A deformed ratchet will not work properly. Tightening strap should always be conducted with a ratchet by moving it manually.

The third parameter: standard tension force (STF) is a force acting on the load held to the floor of a vehicle created by lashing and manually tensioning the strap

This parameter depends on the number and density of teeth of a ratchet, length of a handle and diameter of a roller for winding a strap. The higher STF, the more the strap can be tightened. For example, STF = 1000 daN means that, when lashing a load “from above”, the strap will tie down the pallet to the floor with pressure equal to 1 tonne (force of 10000 N). It is recommended that this parameter be not lower than 550 daN – such value should already allow us to prevent the cargo from moving on the floor of the vehicle. Besides, in some countries (such as Austria and Germany), additional standards are applicable, according to which STF (standard tension force) cannot be lower than 500 daN.

A label also contains information about the allowed extension of a strap. This parameter is expressed as a percentage (%), and, in compliance with EN 12195-2 standard, it cannot exceed 7%. Of course, the shorter extension, the better. I personally would recommend choosing straps with the allowed extension of 4% or maximum 5%.

A label also informs us about the strap length, and, as for two-part straps, about the length of the part with the label sewed in (so to get the full length, the lengths of two parts have to be added).

And the most important thing, a label has to have a marking with “EN 12195-2”, confirming the strap’s compliance with our well-known European standard.

However, a proper selection of properties and number of lashing straps is not enough. Fines can be imposed also for:

– a strap with illegible label. Unfortunately, letters on labels will gradually wear out and finally become obscure/illegible. It is enough that only one of the parameters is hard to read, and the strap may be considered as not fulfilling requirements of EN 12195-2 standard,

– a twisted strap. Even single twisting of a tensed strap causes unequal distribution of forces: higher forces will act on the edge of a twisted strap, and the lower ones on the centre of it, posing a risk of tearing it below LC force,

– a strap with a ratchet placed on the edge of a load. In this case forces acting on the strap will distort the ratchet, which may lead to an uncontrolled release of a ratchet,

– a wet strap. We all know that a wet towel is more difficult to tear. Unfortunately, tie down straps work the other way round. Water particles negatively change the strap’s properties and weaken it,

– a swollen strap. A strap which is soft, clearly thicker and swollen cannot be used anymore to secure loads. Swelling is caused by micro damages of the fibres, most often resulting from fouling (e.g. sand grains),

– worn, torn, cut straps and those with visible changes in their weave structure obviously do not meet the parameters described on the label.

Photo: Example of a damaged label of a restraint strap: due to partially worn out values of LC, SHF and STF, although the strap is compliant with 12195-2 standard, it is impossible to identify its parameters. Using a strap with such a label will definitely end up in a ticket during the inspection.

Summing up, when choosing straps, we should not rely only on their colour

Although, typically, straps from the weakest to the strongest ones will be green, blue, yellow, red and orange respectively, a colour itself is not a guarantee of their parameters. The appropriate properties of a strap can be guaranteed only by its readable label with the marking of EN 12195-2 standard. Note: two-part tie down straps should have two labels, one for each part!

In the following articles I will elaborate on the methods of load securing, fastening straps and calculating the right number of straps according to EN12195-2 standard, I will also touch upon additional equipment which can help us to secure the cargo on a tarpaulin trailer or refrigeration truck.

Before the next journey, check the labels of your straps, to avoid a ticket.

Photo: Pixabay/Jaume Jaquet