This is becoming repetitive, but I will say it once again. Many companies working with e-commerce and omnichannel are seeing their logistics costs increase in an unhealthy manner. Due to the increased pressure on logistics, we also see a labour shortage in many regions.

Due to the above challenges, technological development in logistics is going faster than ever before. Innovation and disruption are two words that are now synonymous with warehouse logistics.

Automating processes to lower costs

As I have written before, the biggest item in the budget is labour costs and the most effective way to reduce this is to automate processes in warehouses. Established automation solutions such as cranes and shuttles are financially expensive. There are a limited number of companies who can make an attractive ROI for such a solution, even if you work with omnichannel. Another aspect is the risk of being stuck in a rigid solution that cannot handle peak times such as Christmas and Black Friday.

There is a need for technology that is more scalable and agile and does not require financial muscles as the established solutions do, which also attracts medium-sized companies in e-commerce. Robotic technology could be an answer to that. The technology is more affordable to a broader array of companies today thanks to advancements in technology and lower costs components.

Collaborative robots

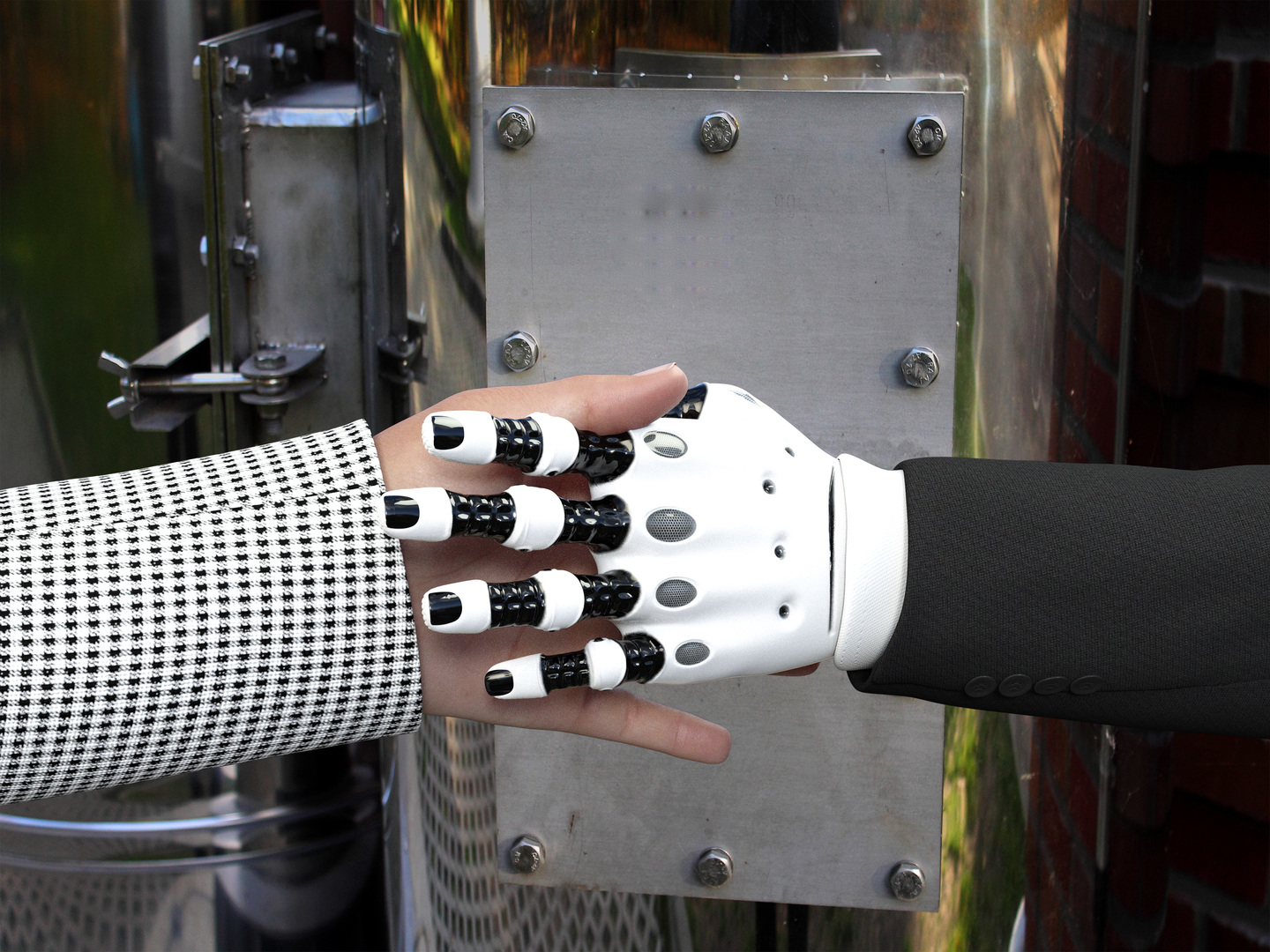

When we hear the word robot, most of us think of a machine anchored to the floor and properly fenced in cages to protect human beings. That is not the type of robots that is of interest for warehouses. We are talking about cobot (collaborative robots) who work in close collaboration with humans thanks to advanced technologies such as AI, lidar/radar, GPS, and the latest connectivity. Cobots are packed with advanced sensors and vision technology to avoid accidents with humans. They are being developed to work close to humans. Thanks to AI and machine learning, the cobots can be versatile and are getting better and better at their tasks over time.

The primary goal with cobots is to complement and augment human labour in the warehouse. The warehouse tasks for cobots are still limited but the technology is still in its infancy. However, development is moving forwards and innovations are developing at a very fast pace. You can find robotics programs at reputable universities such as MIT, Carnegie Mellon, and Georgia Tech for example.

Don’t forget to create value

The ongoing digital transformation in the warehouse logistics market gives a great opportunity for new companies in robotics to create value. RaaS (Robotics as a Service) is a business model that attracts small and medium-sized companies and allows them to compete with the big giants. Cobot technology is very scalable and agile, you can increase the number of cobots when you have peaks in the workload. Robotics companies can offer full-service solutions and provide attractive opportunities to build value for warehouses. Some examples of Robotic companies is 6 River Systems, Righthand Robotics, inVia Robotics and Locus Robotics.

Cobots change the way we think about humans-robots dynamics.

I am sure we will not see any fully robotic or automated warehouses in the near future. However, I am sure that we will have to get used to new colleagues in the warehouse, our cobots.

Roberth Karlsson is a logistics expert and the author of roblogistic.com.

Photo: PxHere